| © PARTDESIGN ApS | Hobrovej 317A | 9200 Aalborg SV | Denmark | +45 70 70 20 46 | cvr 32076033 | www.partdesign.dk |

Developed by XIGRAFFIX

Danish language

From CNC to injection moldingCompared to machining, are mainly two reasons for injection molding - the design freedom and the economic aspect. This requires different glasses, let us in the following look at both and let the reader assess. |

Industrial design |

Product delivery |

| Although there are exceptions, the industrial designer most often has his eyes fixed on the form rather than production. Double Curved surfaces are now no problem to do in an CNC machining center, but the choice of materials and colors is limited and the surface texture is a limitation. The demanding consumer may not know the alternative manufacturing processes, but expect the appearance of the product to be attractive. It is our experience that the aesthetics is increasingly important when comparing industrial products. Function can rarely stand alone, if there are alternative products to choose from. | We often see that companies with smaller series in plastic, have the items manufactured by CNC. Upon the marked introduction, the company may not have been certain about the products success and did not want to invest in a mould. But at some point the quantity may have reached a number, where it makes sense to re-consider a mould. Either for enhancing, re-launching or just reduce the item cost. Everyone can relate to the economic aspect, as it just requires simple calculations. You can see examples below ... |

Product appearance |

One of our customers, develop and sell products for the professional beauty industry. It is a niche market and therefore, they have so far been satisfied with the appearance of the product. In one product, they use 3 CNC machined parts in POM, with a good finish. The sales numbrs has been increasing and the 3 parts account for a not insignificant share in the BOM, so it was natural to look at potential savings.

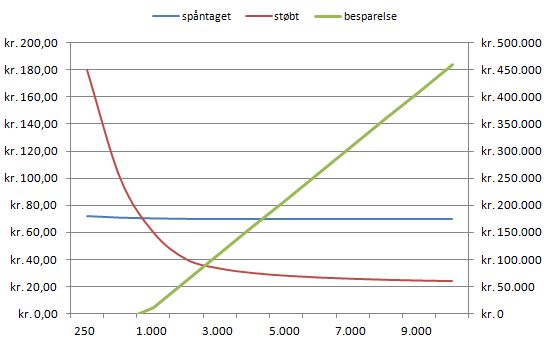

Let us, for the sake of illustration, assume that the CNC machined items together cost 70 DKK, The mould cost 40,000 DKK and three injection molded parts all together cost 20 DKK. As the graph shows, there is break-even already at about 800 sets of plastic parts. So, it was a considerable cost reduction, the customer looked at when they started the project. It required some redesign of the plastic parts, but as a "one-stop-shopping" supplier, we managed the entire process and as a side benefit, the customer has even got its company name embedded in one of the items. |

Download |

| You can play with the numbers yourself, just download the spreadsheet. |

| If you manufacture the items yourself and do not know your actual cost of production, you can download a calculator for CNC cost. Contact us and get a tool + item cost, to increase the accuracy of your calculation. |